Search:

You are here: Home

Products & Services

Products & Services

Product Catalogue

Product Catalogue

Electric Furnace

Electric Furnace

Other Furnaces

Other Furnaces

Regeneration Line of Casting Resin Sand

Regeneration Line of Casting Resin Sand

Products & Services

Products & Services

Product Catalogue

Product Catalogue

Electric Furnace

Electric Furnace

Other Furnaces

Other Furnaces

Regeneration Line of Casting Resin Sand

Regeneration Line of Casting Resin Sand

Product catalogue

-

Power Semiconductor

-

Power Modules & SSR

-

Power Assemblies

-

Assembly Parts

-

Advanced Ceramic

-

Inverter & Soft Starter

-

Electric Furnace

Regeneration Line of Casting Resin Sand

- Features

- Specifications

- Circuits

- Name Instruction

- Outlines

- Gallery

- Download

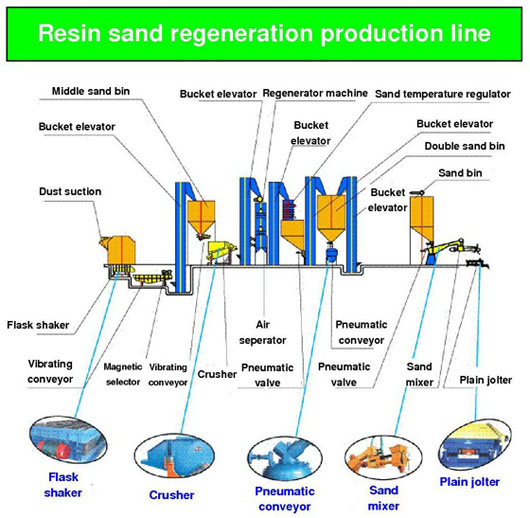

Introduction

The features of the equipment are advanced technology, reliable performance, rational structure, flexible layout, simple application and maintenance. The PLC control system is applied to realize mechatronics integration system. At present, there are 16 series, more than 80 kinds of production for the regeneration production line of resin sand sodium silicate sand and meet the demand of annual 1000 - 30000 tons of resin sand and sodium silicate-bonded sand.

Main Equipment

1. Y335D Belt conveyor

This conveyor is a new type designed according to the special application of casting plant. It is mainly used for conveying the new sand, used sand, molding sand, coat and lime stone as well as the construction material, chemical industry and food processing for all granular or block shape material.

Width of belt:500mm

Width of belt:500mm

Conveying speed:1m/s

Conveying speed:1m/s  Parallel transfer volume:50m3/h

Parallel transfer volume:50m3/h

Power of motor:1.5kW

Power of motor:1.5kW

2. S561 Multi-function vibration regenerator

This regeneration machine is designed for the resin sand or silicate bonded sand regeneration. The main mode is vibration and friction regeneration, also the function of breaking sand shakeout, sieving, demold.

Production rate:1-3 t/h

Production rate:1-3 t/h

Power of motor:2*1.5kW

Power of motor:2*1.5kW

3. Y3715 Bucket elevator

This machine is a vertical transferring machine which is applied in mechanical casting plant. It is mainly used for elevating the used sand, waste sand, new sand, cleaning iron shot, etc. Combined with the belt conveyor and other devices, we can design many kind of transferring system. The features are small external size, less volume and higher elevation level so that the layout drawing will be compact.

Production rate:3-8 t/h

Production rate:3-8 t/h

Power of motor:1.5kW

Power of motor:1.5kW

4. S522II Centrifugal regenerator

The centrifugal machine adopts the principle of dry-process centrifugal regeneration. It is mainly used for used resin sand regeneration. The used sand will be thrown to wear-resisting lining by the high speed rotating blade. And the inert cover on the surface of resin sand will be removed by the rub and collision process between the sand articles, blade and box. According to the process requirement, the process will be repeated for many times till the target achieved.

Production rate:3-5 t/h

Production rate:3-5 t/h

Power of motor:2*3kW

Power of motor:2*3kW

5. S562III air-float separator

The separator is mainly used for separating the powder from the sand of resin sand and sodium silicate sand. The powder should be completely removed from regenerating sand, so that the regenerating sand may meet the process requirement.

Production rate:3-5 t/h

Production rate:3-5 t/h

6. S255T Double-arm sand mixer

The machine is applied to mix the resin sand and silicate bonded sand. The adhesive feeding system consisted of the gear pump, membrane pump and liquid detector so the measurement is accurate, the mixing period is short and the loss of first and last round sand is less. The double-arm of machine rotates flexibly and the available working area is large. The open type sand mixing stir cage is advantage for cleaning or adjusting the blade. The dust collection and deflavour system are combined in the primary and secondary connection as well as the secondary outlet, in order to reduce the content of powder and binder air in the sand. The electric control system is PLC controlled and completely restricting protection. The information displayed by mimic board with reliable operation.

Productivity:3-5t/h

Productivity:3-5t/h

Primary rotating radius:2.75m, Rotary scope:120°

Primary rotating radius:2.75m, Rotary scope:120°

Power of motor:2.2kW

Power of motor:2.2kW

Secondary rotating radius:1.75m(flexible), Rotary scope:270°

Secondary rotating radius:1.75m(flexible), Rotary scope:270°  Power of motor:4kW

Power of motor:4kW

7. S524IV Sand temperature regulator

The main principle of sand temperature regulator: The sand is conveyed to sand temperature regulator from the top of sand temperature regulator and there are water pipes in the sand temperature regulator. The cooling water or hot water continuously flow in the heat sink which assembled with multilevel cooling pipes. Hot sand or cold sand is conveyed to from the water pipes for heating exchange. The sand will be conveyed out when reach the set temperature.

Production rate:3-5 t/h

Production rate:3-5 t/h

8. HD8980 Bag-type dust collector

The series of bag-type dust collector is specially designed for dedusting at the roof or bottom of cement plant storeroom, belt conveyer and collecting dust in a small area and it is also used for dedusting in the industry of casting machinery processing, metallurgy, ceramics, glass, heavy chemicals and food processing. The advantages of dust collector are little volume, large amount of air processing, compact structure, convenient application, strong reliability and so on. This equipment has a good dust collecting performance for large proportion of metal borings, sand for casting and medium proportion of powder.User Requirement

According to the production program, workshop structure and technical requirements, the alkaline phenolic resin and organic material are applied as binder, adopt normal temperature cured resin sand molding process to manufacture heat resistant steel.

Productivity: Steel casting parts 1000ton per year

Productivity: Steel casting parts 1000ton per year

Regeneration capacity of used sand:1-3t/h

Regeneration capacity of used sand:1-3t/h

Recovery rate of used sand:≥95%

Recovery rate of used sand:≥95%

Regeneration sand demold rate:≥26%

Regeneration sand demold rate:≥26%  Ignition loss of regenerated sand:≤3.5%

Ignition loss of regenerated sand:≤3.5%

Powder content of regenerated sand:≤0.8%

Powder content of regenerated sand:≤0.8%

The capacity of mixing sand:5t/h

The capacity of mixing sand:5t/h

The efficiency of removing dust:≥98%

The efficiency of removing dust:≥98%

Regeneration Line of Casting Resin Sand

No

Model

Equipment name

Qty

Power

(kW)remark

1 DK Electric control 1 2 Y335D Belt conveyor 1 1.5 Permanent magnet head pulley is included 3 S561I-A Multi-function vibration regenerator 1 2×1.5 4 Y3715 Bucket elevator 1 1.5 H=8500mm 5 S562III Air-float separator 1 6 S522II Centrifugal regenerator 1 2×*3 7 Y3715 Bucket elevator 1 1.5 H=7000mm 8 C181 Charge level indicator 6 9 Y5610B Sand quantitative device 1 10 S255T Double-arm resin sand mixer 1 4 Imported membrane pump 11 HD8980 Bag-type dust collector 1 15 Included 15kW draught fan 12 XLP/B-9.4 Cyclone dust extractor 1 13 S524Iv Y5620 1 14 Y3715 Bucket elevator 1 1.5 H=7500mm 15 Used and new sand ratio regulator 1 16 Y3712 Bucket elevator 1 1.5 H=7500mm For hoisting new sand 17 L123T Vibration shakeout machine 1 2×3.7 Optional 18 S995 Permanent magnetic separator 1 1.5 Optional 19 S564II Boiling and cooling bed 1 18.5 Optional -

/Upload/7/7331-15351887562.jpg&^&&^&

-

Regeneration Line of Casting Resin Sand

Document Format File Size 0

0 Regeneration Line of Casting Resin Sand Spec Sheet

1.2 MB